Export thread

Stienman's stuff

#1

strawman

strawman

Not necessarily a commitment to create every day, but hey, who knows. I made it through nanowrimo a few years ago, how hard can this be, right? Right?

While I'm posting this today, I created the device last night in an hour or so. It's far from complete, but the basic idea is shown:

A distance sensor, microcontroller (arduino in this case) and speaker allows one to play a note corresponding to how far their hand is from the sensor. Similar to a Theramin, but not as annoying as this sticks to notes on the pentatonic scale, so there is no discord as the player switches from note to note.

Still need to make it easier to play (most of the notes are crowded near the sensor) and add a volume control (using another distance sensor).

Idea given to me by a volunteer at the Ann Arbor Hands on Museum.

While I'm posting this today, I created the device last night in an hour or so. It's far from complete, but the basic idea is shown:

A distance sensor, microcontroller (arduino in this case) and speaker allows one to play a note corresponding to how far their hand is from the sensor. Similar to a Theramin, but not as annoying as this sticks to notes on the pentatonic scale, so there is no discord as the player switches from note to note.

Still need to make it easier to play (most of the notes are crowded near the sensor) and add a volume control (using another distance sensor).

Idea given to me by a volunteer at the Ann Arbor Hands on Museum.

#3

Biannoshufu

Biannoshufu

I think we have our bat cave gadgets engineer

#4

strawman

strawman

I've been helping someone complete their Daft Punk replica helmet. After some effort I finally got the circuit boards in yesterday, assembled all the fiddly bits onto one of them, and wrote a bit of software. I was rewarded with blinking lights - and honestly, there aren't many rewards better than blinking lights:

I'll have to come up with a few more animations and assemble another one to hand over to the client so they can play with it. I haven't received any guidance on dimensions and layout, so this board is primarily a prototype to allow me to test the design and create animations.

I'll have to come up with a few more animations and assemble another one to hand over to the client so they can play with it. I haven't received any guidance on dimensions and layout, so this board is primarily a prototype to allow me to test the design and create animations.

#5

strawman

strawman

Sandbox with integrated lid/bench:

We had an old sandbox that was just 4 five foot boards screwed and set on a sandy part of our backyard, with added play sand from the hardware store. While treated lumber has its place, I don't want to use it in the garden or where my kids will have regular contact with it, so the sandbox lasted about three years. During that time it became was also occasionally used by cats, which was less than ideal. Due to its alternate uses I've been reluctant to build another one. Tarps are annoying, collect water (breed mosquitos), and no one ever puts them back on. Prefabricated plastic ones are too small, too shallow, and also tend to collect water.

My wife wanted to have another one, though, and wanted it before the birthday of boy #6, who is about to turn two, and is currently really enjoying digging up plants in the garden. After a few days research she found this:

http://www.amazon.com/gp/product/B0038609BI

So I supersized it and made one:

Still need to dig out the center another half foot and add a bunch of sand, but I'm pretty happy with how it turned out. The bottom is cedar to avoid rot, and the top/bench is pine (well, SPF anyway) which won't rot as quickly since it's not in the sand/dirt. We'll probably paint all the pine anyway. It's modified a bit - the whole thing is 6'x8', but the interior box is only 5'x8'. There are angled cuts on the outside for the bench supports to rest against, and half the bench is outside the box, which means there's only six inches of sand under the bench, rather than a foot. Uses less sand, and there's less area to collect leaves and other detritus.

I ended up changing the design after purchasing wood and hinges. Rather than two 8' benches I ended up cutting them in half and having four smaller 4' benches which should be easier to open, but I was 3 hinges short, so I still have a few hinges and boards to add to the far side of the box. It's usable as-is now, though.

Cost about $160, and I spent about 8 hours total building it.

We had an old sandbox that was just 4 five foot boards screwed and set on a sandy part of our backyard, with added play sand from the hardware store. While treated lumber has its place, I don't want to use it in the garden or where my kids will have regular contact with it, so the sandbox lasted about three years. During that time it became was also occasionally used by cats, which was less than ideal. Due to its alternate uses I've been reluctant to build another one. Tarps are annoying, collect water (breed mosquitos), and no one ever puts them back on. Prefabricated plastic ones are too small, too shallow, and also tend to collect water.

My wife wanted to have another one, though, and wanted it before the birthday of boy #6, who is about to turn two, and is currently really enjoying digging up plants in the garden. After a few days research she found this:

http://www.amazon.com/gp/product/B0038609BI

So I supersized it and made one:

Still need to dig out the center another half foot and add a bunch of sand, but I'm pretty happy with how it turned out. The bottom is cedar to avoid rot, and the top/bench is pine (well, SPF anyway) which won't rot as quickly since it's not in the sand/dirt. We'll probably paint all the pine anyway. It's modified a bit - the whole thing is 6'x8', but the interior box is only 5'x8'. There are angled cuts on the outside for the bench supports to rest against, and half the bench is outside the box, which means there's only six inches of sand under the bench, rather than a foot. Uses less sand, and there's less area to collect leaves and other detritus.

I ended up changing the design after purchasing wood and hinges. Rather than two 8' benches I ended up cutting them in half and having four smaller 4' benches which should be easier to open, but I was 3 hinges short, so I still have a few hinges and boards to add to the far side of the box. It's usable as-is now, though.

Cost about $160, and I spent about 8 hours total building it.

#6

Chad Sexington

Chad Sexington

That's really awesome. Would you be able to provide a list of materials/plans? I think that'd be something my sister's boyfriend and I could build for my niece and step-niece.

#7

strawman

http://ana-white.com/2011/10/plans/sand-box-built-seats

Mine is slightly different, mostly just larger, but let me know if you have any questions about the differences.

strawman

Fortunately for both of us, I don't have to write up plans. Someone on DIY.stackexchange.com pointed out that the design isn't new, and plans are available for free online here:That's really awesome. Would you be able to provide a list of materials/plans? I think that'd be something my sister's boyfriend and I could build for my niece and step-niece.

http://ana-white.com/2011/10/plans/sand-box-built-seats

Mine is slightly different, mostly just larger, but let me know if you have any questions about the differences.

#8

Chad Sexington

Chad Sexington

As previously noted: you're a damn hero.Fortunately for both of us, I don't have to write up plans. Someone on DIY.stackexchange.com pointed out that the design isn't new, and plans are available for free online here:

http://ana-white.com/2011/10/plans/sand-box-built-seats

Mine is slightly different, mostly just larger, but let me know if you have any questions about the differences.

#9

strawman

strawman

Someone contacted me about my theremin I posted above, and asked if I could make an instrument quality version with multiple scales, keys, octaves, and a few different waveforms. So I tinkered with that yesterday and was able to do this:

It has some severe problems, as you can hear. The harmonics and beat frequencies are due to the fact that I'm only producing sound at a 5kHz sample rate and 8 bits. Also there's a ton of jitter due to the way the analog converter is set up. I could fix some of those things with a great deal more time, but I can instead purchase a more capable microcontroller for less than what I charge in an hour, it'll save me several hours, and I'll be able to run it at 44.1kHz with 12 bits of resolution with no jitter, a significant improvement. And this will require very little additional time, allowing me to spend time on the scales and keys, rather than forcing a difficult task onto a limited microcontroller. I enjoy trying to make limited hardware perform exceptional tasks - it's a fascinating puzzle - but it's very time consuming and I can't get it to them before their next concert if I'm fiddling around so much.

It has some severe problems, as you can hear. The harmonics and beat frequencies are due to the fact that I'm only producing sound at a 5kHz sample rate and 8 bits. Also there's a ton of jitter due to the way the analog converter is set up. I could fix some of those things with a great deal more time, but I can instead purchase a more capable microcontroller for less than what I charge in an hour, it'll save me several hours, and I'll be able to run it at 44.1kHz with 12 bits of resolution with no jitter, a significant improvement. And this will require very little additional time, allowing me to spend time on the scales and keys, rather than forcing a difficult task onto a limited microcontroller. I enjoy trying to make limited hardware perform exceptional tasks - it's a fascinating puzzle - but it's very time consuming and I can't get it to them before their next concert if I'm fiddling around so much.

#11

strawman

strawman

Got the new hardware in for the theremin project, and now the hardware is (nearly) complete and sounding good:

My client has an antique (ish) radio box he's going to put this inside, so the case I'm using (discarded light fixture) is merely for my convenience in keeping the knobs in order and easy to manipulate.

It'll also make it easier to show off at the local geek show'n'tell (gotech ann arbor) Tuesday evening. Hopefully I'll get a few scales and keys in there, and maybe the continuous (ie, more like a theremin without discrete note steps) mode prior to the meeting.

Anyway, barring any difficulties I hope to ship this to my client early next week. He chose my half rate, which I offer if clients don't require exclusive rights to the work produced, and this is an interesting enough project that I may document it, make it open source and/or kickstart it.

My client has an antique (ish) radio box he's going to put this inside, so the case I'm using (discarded light fixture) is merely for my convenience in keeping the knobs in order and easy to manipulate.

It'll also make it easier to show off at the local geek show'n'tell (gotech ann arbor) Tuesday evening. Hopefully I'll get a few scales and keys in there, and maybe the continuous (ie, more like a theremin without discrete note steps) mode prior to the meeting.

Anyway, barring any difficulties I hope to ship this to my client early next week. He chose my half rate, which I offer if clients don't require exclusive rights to the work produced, and this is an interesting enough project that I may document it, make it open source and/or kickstart it.

#12

PatrThom

PatrThom

Oh hey @stienman here's something that you may find useful in your design process (current or future).

Autodesk and Circuits.io partner to launch a free electronics design tool: 123D Circuits.

--Patrick

Autodesk and Circuits.io partner to launch a free electronics design tool: 123D Circuits.

--Patrick

#13

strawman

strawman

Here's the final demo video of the theremin for this client:

Hopefully he has no further changes so I can ship it this week and get the rest of his payment. He hasn't yet chosen the exclusive licensing option, and I have a few other people interested enough in it that I'm considering creating a different version for sale and/or kickstarter. I doubt it will sell much, but I believe there are a few artists that would like one.

Anyway, fun project.

Hopefully he has no further changes so I can ship it this week and get the rest of his payment. He hasn't yet chosen the exclusive licensing option, and I have a few other people interested enough in it that I'm considering creating a different version for sale and/or kickstarter. I doubt it will sell much, but I believe there are a few artists that would like one.

Anyway, fun project.

#15

strawman

strawman

I'm looking at both for other projects. They have very intriguing possibilities, and if inexpensive could be more interesting than the raspberry pi. The galileo doesn't have HDMI out, though, which limits it a bit. However I expect the TRE to be more power hungry.

Would be nice if they really were cost competitive with the pi. Still, $60 for the galileo isn't bad. Hopefully the Tre comes in low as well.

Don't forget the Yun is already available, has linux onboard, and ethernet, wifi, and the wifi can act as an access point. It runs an open source wifi router distro.

Would be nice if they really were cost competitive with the pi. Still, $60 for the galileo isn't bad. Hopefully the Tre comes in low as well.

Don't forget the Yun is already available, has linux onboard, and ethernet, wifi, and the wifi can act as an access point. It runs an open source wifi router distro.

#16

strawman

strawman

I've mentioned here and there about a project I recently worked on which used nearly a mile of LED rope lighting and a custom light sequencer, but couldn't give any details as to what it actually was.

It's an air hockey rink big enough to rollerblade on. The puck rides on a cushion of air, allowing for significantly faster puck travel than in an ice hockey game. Doesn't need tons of refrigeration, can be used outdoors in the summer, and has an underfloor lighting system for indoor, and outdoor evening play.

I'm not involved in the kickstarter, but in it you can see the prototype I worked on:

Since they finally started the kickstarter for the next prototype, 17 time larger than the prototype I worked on, I figured you might be interested in knowing what it was I was talking. All the filmed shots of the 24'x40' rink shows the underfloor lighting system I designed, built, installed, ripped up, and reinstalled with brighter lighting due to changing customer requirements. It uses standard stage lighting dimmers with a custom arduino controller I developed for it.

They asked me to help them build the 200'x90' regulation size rink they are kick starting now, but I've declined due to time constraints. I did a lot of the pre-design work, though, and it's massive, should be amazing assuming they can get someone to build it for them in a matter of weeks...

Anyway. Blinking lights, thought you might get a kick out of it.

Also, I have a half mile of incandescent warm white rope lighting to sell, send me an offer...

It's an air hockey rink big enough to rollerblade on. The puck rides on a cushion of air, allowing for significantly faster puck travel than in an ice hockey game. Doesn't need tons of refrigeration, can be used outdoors in the summer, and has an underfloor lighting system for indoor, and outdoor evening play.

I'm not involved in the kickstarter, but in it you can see the prototype I worked on:

Since they finally started the kickstarter for the next prototype, 17 time larger than the prototype I worked on, I figured you might be interested in knowing what it was I was talking. All the filmed shots of the 24'x40' rink shows the underfloor lighting system I designed, built, installed, ripped up, and reinstalled with brighter lighting due to changing customer requirements. It uses standard stage lighting dimmers with a custom arduino controller I developed for it.

They asked me to help them build the 200'x90' regulation size rink they are kick starting now, but I've declined due to time constraints. I did a lot of the pre-design work, though, and it's massive, should be amazing assuming they can get someone to build it for them in a matter of weeks...

Anyway. Blinking lights, thought you might get a kick out of it.

Also, I have a half mile of incandescent warm white rope lighting to sell, send me an offer...

#17

PatrThom

--Patrick

PatrThom

Don't think I'm not tempted!I have a half mile of incandescent warm white rope lighting to sell, send me an offer...

--Patrick

#18

Chad Sexington

Chad Sexington

HmmmAlso, I have a half mile of incandescent warm white rope lighting to sell, send me an offer...

#20

strawman

strawman

That's very cool!

What is needed now is an automatic over-easy egg cooker so he gets fresh eggs when he wakes up in the morning.

What is needed now is an automatic over-easy egg cooker so he gets fresh eggs when he wakes up in the morning.

#21

PatrThom

PatrThom

You need to be a bit more surreptitious with your projects from now on. People might notice.

http://arstechnica.com/security/201...its-terrifyingly-easy-to-hack-traffic-lights/

--Patrick

http://arstechnica.com/security/201...its-terrifyingly-easy-to-hack-traffic-lights/

--Patrick

#24

PatrThom

PatrThom

I wondered what you had been up to. We haven't seen you much.

This is what you've been doing? Building torture devices?

--Patrick

This is what you've been doing? Building torture devices?

--Patrick

#26

strawman

strawman

Okey dokey. I've not only made a web page, but spent a good chunk of time making an animated 3D rendering of it so people who want to make their own understand how it goes together. Since I made the rendering, you must look at it.

LOOK AT IT.

The webpage is http://thermalgrill.com if you are so inclined. It has more pictures and video. Feel free to freeze frame when my face looks funny and add derp text.

LOOK AT IT.

The webpage is http://thermalgrill.com if you are so inclined. It has more pictures and video. Feel free to freeze frame when my face looks funny and add derp text.

#27

strawman

strawman

In the last 24 hours the video has had over 6,000 views, and the webpage has been visited 400 times due mostly to an article on hackaday.com. One of Make Magazine's blog contributors is creating a writeup for it as well, hopefully that'll go up in a day or two.

Still, out of those thousands of people that have viewed it the video and hundreds who've viewed the website, the website has only collected 4 emails of people interested in more information.

This is not going to be a productive kickstarter.

I wonder if I need to focus more on the "Dune Pain Box" aspect of it and less on the sciencey "thermal grill illusion" aspect...

Still, out of those thousands of people that have viewed it the video and hundreds who've viewed the website, the website has only collected 4 emails of people interested in more information.

This is not going to be a productive kickstarter.

I wonder if I need to focus more on the "Dune Pain Box" aspect of it and less on the sciencey "thermal grill illusion" aspect...

#29

evilmike

evilmike

http://makezine.com/2015/07/07/this-simple-trick-makes-you-feel-like-youre-being-burned/One of Make Magazine's blog contributors is creating a writeup for it as well, hopefully that'll go up in a day or two.

#30

Ravenpoe

Yeah, I realize the original post was from 2 years ago, but since this thread is already necro'd, deal with it.

Ravenpoe

If you misbehave again, it's back in the hole!

Yeah, I realize the original post was from 2 years ago, but since this thread is already necro'd, deal with it.

#31

strawman

strawman

In 2014 we moved, I mounted the projector to the ceiling, and we bought a decent surround sound receiver. Since that time the receiver and all other entertainment stuff has been sitting on a too-large table, within easy reach of the toddlers, with difficult to get to cables and wires.

Today I finally made a little two shelf corner entertainment center for it. The bottom is for the bluray, tv tuner (projectors don't have tuners), and game console. The top has a swivel/sliding mechanism which I salvaged from an old entertainment center, meant to hold big CRT TVs. I added a bar and some bolts strategically located so when the swivel/slide mechanism was pushed in, it lined up with the front of the shelf, and when pulled out it rotates the receiver a little over 90 degrees so the back is easy to access. The cords and wires are then zip tied to the bar so you can pull the receiver out without worry over stressing a wire or pulling out a connector.

Used junk wood from an old shelving unit, so the only thing I purchased for this was the spray paint. Took most of the day, but it's done and we've recovered a lot of dead floor space in that room, which is good 'cause we've got a lot of people to fit in there when we're watching a movie together.

It's functional, but it doesn't look good. Visually unbalanced, too top heavy. I'm glad I used free materials and didn't waste good hardwood on this design. I'm probably never going to get around to upgrading it unless I add a lot more equipment, but it does what it needs to do, and lives in a dark corner of a dark room anyway. Given the size of the receiver and my desire for easy access I'm not sure what I would do to fix the unbalanced look anyway. Something to mull over the next few years I suppose.

Today I finally made a little two shelf corner entertainment center for it. The bottom is for the bluray, tv tuner (projectors don't have tuners), and game console. The top has a swivel/sliding mechanism which I salvaged from an old entertainment center, meant to hold big CRT TVs. I added a bar and some bolts strategically located so when the swivel/slide mechanism was pushed in, it lined up with the front of the shelf, and when pulled out it rotates the receiver a little over 90 degrees so the back is easy to access. The cords and wires are then zip tied to the bar so you can pull the receiver out without worry over stressing a wire or pulling out a connector.

Used junk wood from an old shelving unit, so the only thing I purchased for this was the spray paint. Took most of the day, but it's done and we've recovered a lot of dead floor space in that room, which is good 'cause we've got a lot of people to fit in there when we're watching a movie together.

It's functional, but it doesn't look good. Visually unbalanced, too top heavy. I'm glad I used free materials and didn't waste good hardwood on this design. I'm probably never going to get around to upgrading it unless I add a lot more equipment, but it does what it needs to do, and lives in a dark corner of a dark room anyway. Given the size of the receiver and my desire for easy access I'm not sure what I would do to fix the unbalanced look anyway. Something to mull over the next few years I suppose.

#34

strawman

strawman

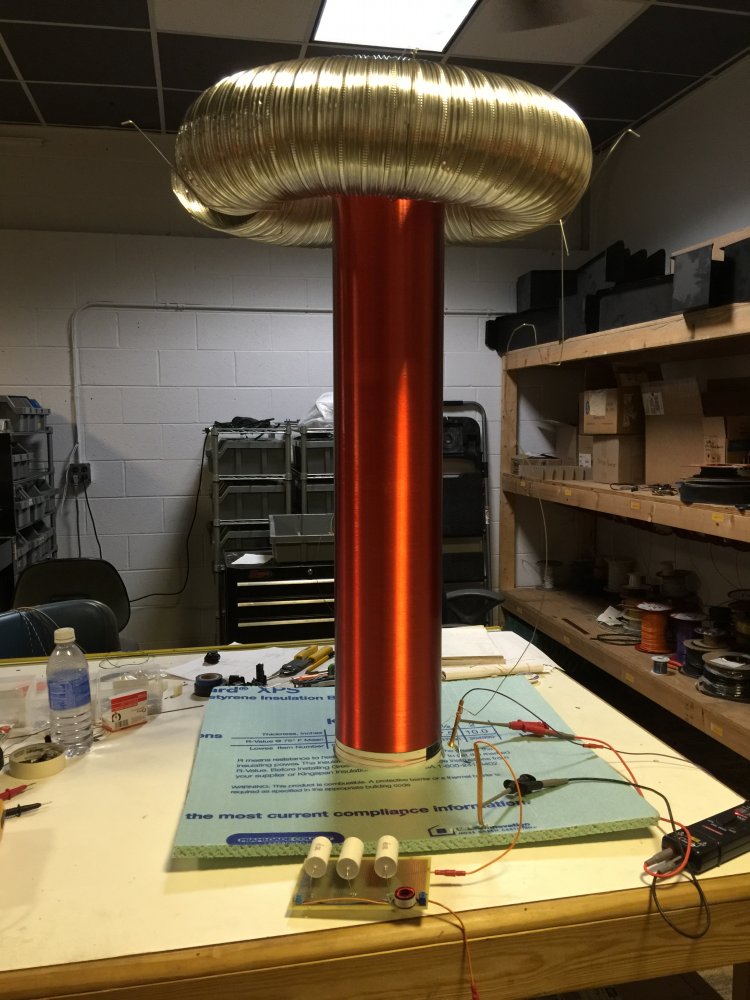

A coworker and I are building a tesla coil. Even though it's badly tuned and not fully assembled, we were able to generate an arc with it, so it's already generating at least 60,000 volts:

#35

strawman

strawman

Here's what it looks like right now:

[DOUBLEPOST=1464988277,1464988217][/DOUBLEPOST]That's about half a kilometer of wire on a 6" pvc pipe, with the bottom coil upside down so you can't see the copper primary coil.

[DOUBLEPOST=1464988277,1464988217][/DOUBLEPOST]That's about half a kilometer of wire on a 6" pvc pipe, with the bottom coil upside down so you can't see the copper primary coil.

#37

strawman

strawman

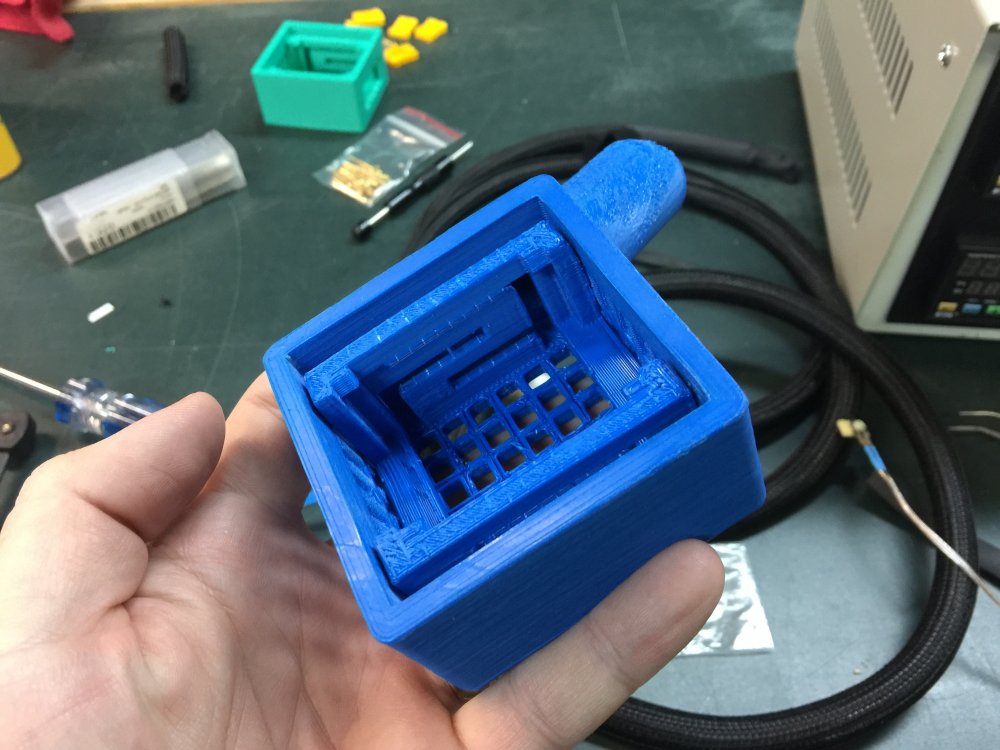

A local neurosurgeon commissioned a custom thermal grill so he can see if it can replace more expensive non damaging pain devices for pain neural pathway studies. Should be done next week, here's what it looks like:

The head is 3D printed and the metal pieces are custom milled on my tiny hand controlled milling machine. Had a huge learning curve, and went several times over my original estimated time (fixed bid, though, so I earned experience more than money due to my poor estimation skills), and so I'm glad it's nearly done, and even happier that it works as well as the previous thermal grill I made.

The plastic head is a single 3D printed part with a floating cage inside that holds the grill. The floating is accomplished with springs built into the design so that pressure sensors can tell how much pressure is being used to hold the grill against the test subject's skin.

The head is 3D printed and the metal pieces are custom milled on my tiny hand controlled milling machine. Had a huge learning curve, and went several times over my original estimated time (fixed bid, though, so I earned experience more than money due to my poor estimation skills), and so I'm glad it's nearly done, and even happier that it works as well as the previous thermal grill I made.

The plastic head is a single 3D printed part with a floating cage inside that holds the grill. The floating is accomplished with springs built into the design so that pressure sensors can tell how much pressure is being used to hold the grill against the test subject's skin.

#38

PatrThom

PatrThom

Is it worth finishing with acetone vapor, or would that throw off the strain gauge too much (or destroy the part!)?

--Patrick

--Patrick

#39

Denbrought

Denbrought

AFAIK it takes some effort to get acetone baths to perform consistently and evenly. If he was producing many of these it might be worth the R&D time/effort/materials, otherwise he's just introducing a bunch of variance (requiring extra design tolerance) into all the pieces.Is it worth finishing with acetone vapor, or would that throw off the strain gauge too much (or destroy the part!)?

--Patrick

#40

strawman

- They're fine with the finish (increases grip anyway)

- It would take a lot more time, which I've already overspent

- If I make a mistake printing another one and cleaning the supports out along with some internal sanding so the carrier moves smoothly takes 6 or more hours, so I'm not keen on learning how to do the acetone vapor smoothing when the cost of making a mistake is so high.

I did use some flame heat (propane touch) to smooth a little bit of it, and eventually I'll play with acetone vapor smoothing, but not for this project.

I do have several prints that I can't use so I have test pieces when I decide to experiment.

I'm using force sensing resistors, not sure if they'd withstand acetone (I doubt it though) but if I were to do any post processing I'd do it with nothing else installed anyway.

So once I have a method and equipment set up then I don't think I'd have any issue with doing it for one-off projects like this.

As neat as this looks I still have a long way to go anyway. There are issues I still had at the end which won't affect use or operation, but should be improved on. For instance the printer is set up to over-extrude slightly, which helps layer adhesion, but messes with the build size, further ABS shrinks when it cools and I didn't account for that. I made the model fully parametric (in OpenScad for the curious - I did the prototype in fusion 360, but I'm a programmer at heart) so through iterative design I just accounted for any minor issues by adjusting the variables, but need to be able to create parts that are better than the current +/- .25mm accuracy I believe I'm currently getting. That's just too much variance for a lot of work that interfaces with other components.[DOUBLEPOST=1485542281,1485542207][/DOUBLEPOST]Oh, another reason not to finish it: The client is really excited about 3D printing and making it look like an injection molded part would actually be disappointing to them, since they intend to show it around and emphasize the 3D printed part.

strawman

Nope:Is it worth finishing with acetone vapor, or would that throw off the strain gauge too much (or destroy the part!)?

--Patrick

- They're fine with the finish (increases grip anyway)

- It would take a lot more time, which I've already overspent

- If I make a mistake printing another one and cleaning the supports out along with some internal sanding so the carrier moves smoothly takes 6 or more hours, so I'm not keen on learning how to do the acetone vapor smoothing when the cost of making a mistake is so high.

I did use some flame heat (propane touch) to smooth a little bit of it, and eventually I'll play with acetone vapor smoothing, but not for this project.

I do have several prints that I can't use so I have test pieces when I decide to experiment.

I'm using force sensing resistors, not sure if they'd withstand acetone (I doubt it though) but if I were to do any post processing I'd do it with nothing else installed anyway.

Yes and no. I will eventually set up a chamber for smoothing and if I was already experienced with the process I would have simply included it as part of my iterative design. I printed 3 carriers before I designed the enclosure, then printed 2 of those before I was happy with it, then printed 3 more to find the best orientation on the printer (combination of support and adhesion issues led to warping, and my new printer doesn't have a heated, draft free enclosure like the old one did, so the problems were troublesome.)AFAIK it takes some effort to get acetone baths to perform consistently and evenly. If he was producing many of these it might be worth the R&D time/effort/materials, otherwise he's just introducing a bunch of variance (requiring extra design tolerance) into all the pieces.

So once I have a method and equipment set up then I don't think I'd have any issue with doing it for one-off projects like this.

As neat as this looks I still have a long way to go anyway. There are issues I still had at the end which won't affect use or operation, but should be improved on. For instance the printer is set up to over-extrude slightly, which helps layer adhesion, but messes with the build size, further ABS shrinks when it cools and I didn't account for that. I made the model fully parametric (in OpenScad for the curious - I did the prototype in fusion 360, but I'm a programmer at heart) so through iterative design I just accounted for any minor issues by adjusting the variables, but need to be able to create parts that are better than the current +/- .25mm accuracy I believe I'm currently getting. That's just too much variance for a lot of work that interfaces with other components.[DOUBLEPOST=1485542281,1485542207][/DOUBLEPOST]Oh, another reason not to finish it: The client is really excited about 3D printing and making it look like an injection molded part would actually be disappointing to them, since they intend to show it around and emphasize the 3D printed part.

#41

strawman

strawman

I've been wanting a good, large structure for a tire swing for some time now, so I've recently been noodling over the design and costs. My dad said he'd be visiting this previous week, and he asked if there was a project he could help with, since we tend to bond over building things. So I put the tire swing project on the fast track and we built this:

It's essentially an octagon, but two side opposite each other are 12 feet long, while the other six sides are only 10 feet long. The two twelve foot wide sides are for swings that go in all directions (aka, tire swings), as long as they only hang 6-7 feet from the top beam. So we have room for a tire swing, and a ring/net swing (already in place on the right). We will leave one side open, so the remaining five will be filled with other swings of various kinds. Probably a few bench swings, a few hammocks. Maybe we'll outfit one as a picnic table (that probably won't swing... probably). We intend to have multiple fasteners in each space (eventually) so we can reconfigure it as needed. So all hammocks for sleeping outside in the summer, or all picnic tables for a party, for instance. Would be interesting to make a double bench swing that faces each other with a table in the middle, but I'm guessing that would be strange.

The large bays use two 6x6 (140mm square cross section) treated posts each, with 4x6 posts for the remaining four posts, and all the posts go 4 feet (1.2m) in the ground with a suitable amount of concrete below and around the bottom of the post. The posts are notched so the headers rest on top of the notches and bolt into the posts. We will be adding some additional beams across top so the posts share side loads better, and the posts and a few other bits need more wood stain so it all matches the header color.

Eventually we'd like to put some sort of roof over it, but that's going to have to wait, at least until we can afford to fill it with swings. We will almost certainly have a fire pit in the middle.

We did run into one electrical wire during digging, but we're fairly certain it's an unused wire for a pool the previous owners had (only 12awg) , and I believe I've already located its termination inside the house (which was cut in a crawlspace) so I wired up an outlet on one of the posts, and if I'm correct then eventually I'll connect the cut wire in the house and have electricity out there.

Here's the area the morning after digging the holes. We rented a little stand-on mini skid steer with a 16" (40cm) diameter auger on it. By the time I got to the eighth hole I was able to do it in under 15 minutes. They have to be deeper than 4 feet (1.2m) to avoid the effects of frost heaving. Here in southern Michigan it's possible for the ground to freeze up to 42" deep, and if there's water under a structure, the freezing water may push structures out of the ground. So while I wanted deep holes to provide good support anyway, they needed to be this deep so none of the posts would be pushed out of the ground slowly over several winters.

Below you'll see the water that collected in them overnight (mostly groundwater), and consistency of the soil (all clay), and the cut wire almost in the middle of the hole.

That day we put 1 bag of concrete in the bottom of each hole, creating thick pads for the posts to rest on, preventing them from snicking into the ground. The following day we put the posts in, spaced them apart, plumbed them straight, poured another bag's worth of concrete in the bottom to hold each post down (the posts had screws in the bottom to embed them firmly into the concrete), and then fill the remainder of the holes with dirt.

We built a support structure around the middle to keep everything in place when we were pouring concrete, and left it there so we could stand on it while preparing the tops of the posts to receive the headers.

I didn't think through how I was going to notch the posts and connect the headers, so I spent nearly half a day working it out, and when we were planning the location of the set it took us over half a day to figure out where it was going to be and how it was going to be oriented. Reached a stalemate, in fact, until I realized we could take down a pine tree, then suddenly everything fell into place. This was supposed to be a 3 day project, but we finished it up this morning after about 5 days of work.

Learned a lot, would do a few things differently if I had to do it over. Still lots of little things to do - attach the swings, level and grass the area, put in a fire pit, etc, etc, etc. But the major portions are done and the rest can be done in little 1-2 hour projects here and there.

Lots of fun, but glad it's done![DOUBLEPOST=1494876210,1494875986][/DOUBLEPOST]Oh, and for those wondering, frost heaving is why basements are more common up north than in the south. If you have to dig a foundation 4 feet down to avoid frost heave, you might as well dig another 4 feet and have a basement. The cost isn't that much more.

It's essentially an octagon, but two side opposite each other are 12 feet long, while the other six sides are only 10 feet long. The two twelve foot wide sides are for swings that go in all directions (aka, tire swings), as long as they only hang 6-7 feet from the top beam. So we have room for a tire swing, and a ring/net swing (already in place on the right). We will leave one side open, so the remaining five will be filled with other swings of various kinds. Probably a few bench swings, a few hammocks. Maybe we'll outfit one as a picnic table (that probably won't swing... probably). We intend to have multiple fasteners in each space (eventually) so we can reconfigure it as needed. So all hammocks for sleeping outside in the summer, or all picnic tables for a party, for instance. Would be interesting to make a double bench swing that faces each other with a table in the middle, but I'm guessing that would be strange.

The large bays use two 6x6 (140mm square cross section) treated posts each, with 4x6 posts for the remaining four posts, and all the posts go 4 feet (1.2m) in the ground with a suitable amount of concrete below and around the bottom of the post. The posts are notched so the headers rest on top of the notches and bolt into the posts. We will be adding some additional beams across top so the posts share side loads better, and the posts and a few other bits need more wood stain so it all matches the header color.

Eventually we'd like to put some sort of roof over it, but that's going to have to wait, at least until we can afford to fill it with swings. We will almost certainly have a fire pit in the middle.

We did run into one electrical wire during digging, but we're fairly certain it's an unused wire for a pool the previous owners had (only 12awg) , and I believe I've already located its termination inside the house (which was cut in a crawlspace) so I wired up an outlet on one of the posts, and if I'm correct then eventually I'll connect the cut wire in the house and have electricity out there.

Here's the area the morning after digging the holes. We rented a little stand-on mini skid steer with a 16" (40cm) diameter auger on it. By the time I got to the eighth hole I was able to do it in under 15 minutes. They have to be deeper than 4 feet (1.2m) to avoid the effects of frost heaving. Here in southern Michigan it's possible for the ground to freeze up to 42" deep, and if there's water under a structure, the freezing water may push structures out of the ground. So while I wanted deep holes to provide good support anyway, they needed to be this deep so none of the posts would be pushed out of the ground slowly over several winters.

Below you'll see the water that collected in them overnight (mostly groundwater), and consistency of the soil (all clay), and the cut wire almost in the middle of the hole.

That day we put 1 bag of concrete in the bottom of each hole, creating thick pads for the posts to rest on, preventing them from snicking into the ground. The following day we put the posts in, spaced them apart, plumbed them straight, poured another bag's worth of concrete in the bottom to hold each post down (the posts had screws in the bottom to embed them firmly into the concrete), and then fill the remainder of the holes with dirt.

We built a support structure around the middle to keep everything in place when we were pouring concrete, and left it there so we could stand on it while preparing the tops of the posts to receive the headers.

I didn't think through how I was going to notch the posts and connect the headers, so I spent nearly half a day working it out, and when we were planning the location of the set it took us over half a day to figure out where it was going to be and how it was going to be oriented. Reached a stalemate, in fact, until I realized we could take down a pine tree, then suddenly everything fell into place. This was supposed to be a 3 day project, but we finished it up this morning after about 5 days of work.

Learned a lot, would do a few things differently if I had to do it over. Still lots of little things to do - attach the swings, level and grass the area, put in a fire pit, etc, etc, etc. But the major portions are done and the rest can be done in little 1-2 hour projects here and there.

Lots of fun, but glad it's done![DOUBLEPOST=1494876210,1494875986][/DOUBLEPOST]Oh, and for those wondering, frost heaving is why basements are more common up north than in the south. If you have to dig a foundation 4 feet down to avoid frost heave, you might as well dig another 4 feet and have a basement. The cost isn't that much more.

#42

PatrThom

PatrThom

Shouldn't be too much more work to add a bi-level vented roof to the structure, you think? That'd keep it from being ripped off by the wind but still provide shelter for whatever you have going on below (and a place for the firepit to vent smoke, besides).

--Patrick

--Patrick

#43

strawman

strawman

My wife is already trying to get me to work on a roofing solution, and that's definitely one of the contenders. Cost is higher, but there are many benefits.

I need to run a gofundme for this...

I need to run a gofundme for this...

#44

Dei

Dei

You aren't going to put solar tiles on a swing set are you? >.>My wife is already trying to get me to work on a roofing solution, and that's definitely one of the contenders. Cost is higher, but there are many benefits.

I need to run a gofundme for this...

#45

PatrThom

--Patrick

PatrThom

Well, if he did, he wouldn't have to run the electric out there for the fans, now would he?You aren't going to put solar tiles on a swing set are you? >.>

--Patrick

#46

strawman

strawman

Oof, no, those are uselessly expensive! We probably won't mount solar anything on this, but it's an option we aren't ruling out.You aren't going to put solar tiles on a swing set are you? >.>

#47

strawman

strawman

So I found a free 56 foot antenna tower on Craigslist, and took it home.

Had to disassemble it first, though.

After removing two antennas and three 8 foot sections I opted to tilt the remaining 32 feet over and disassemble on the ground:

Lots of work, but I got about $1,000 worth of ham radio antennas and a rotor, as well as the $1,700 tower for about $500 for the tools and materials I bought to take it down. Plus the 20 hours it took to do so.

It'll cost more in materials, permits, and repainting to put it back up on my property, but I expect it'll still be an overall savings and hopefully down the road I can use it to get real high speed internet wirelessly.

Had to disassemble it first, though.

After removing two antennas and three 8 foot sections I opted to tilt the remaining 32 feet over and disassemble on the ground:

Lots of work, but I got about $1,000 worth of ham radio antennas and a rotor, as well as the $1,700 tower for about $500 for the tools and materials I bought to take it down. Plus the 20 hours it took to do so.

It'll cost more in materials, permits, and repainting to put it back up on my property, but I expect it'll still be an overall savings and hopefully down the road I can use it to get real high speed internet wirelessly.

#48

PatrThom

PatrThom

Goodness, but you have an active project life.

Now, are you going to attach some guy-wires and mount a windmill on the top, too?

--Patrick

Now, are you going to attach some guy-wires and mount a windmill on the top, too?

--Patrick

#49

strawman

strawman

Oh, and that antenna at the top? That's a 28' x 14' shortwave antenna. I didn't realize it was that big from the ground...

#51

strawman

strawman

No, it's not strong enough for that. Maybe a small one, but it can only support a 20-30 square foot wind load up to 80mph winds, so it's a no go for wind energy.Goodness, but you have an active project life.

Now, are you going to attach some guy-wires and mount a windmill on the top, too?

--Patrick

#52

PatrThom

--Patrick

PatrThom

That's why I suggested the guy-wires, because I assume they would up the wind load tolerance.No, it's not strong enough for that. Maybe a small one, but it can only support a 20-30 square foot wind load up to 80mph winds, so it's a no go for wind energy.

--Patrick

#53

strawman

strawman

Ah. I suppose I could beef it up, but guy wires are very annoying, and they'd buy me maybe a few hundred watts additional of intermittent power.That's why I suggested the guy-wires, because I assume they would up the wind load tolerance.

--Patrick

#54

PatrThom

PatrThom

Well, if you need another one, let me know. I think my father still has the pieces of his from when he ran a taxi company. No idea what sort of condition they're in, since the segments have been stacked up lengthwise on the ground for who knows how long, but y'know...potentially free.

--Patrick

--Patrick

#55

strawman

strawman

I am interested. I'm going to need another one at the end of the potential internet link, so if you wouldn't mind asking him about the size or make/model there's a possibility I'd make the trek to get it and put it to use.Well, if you need another one, let me know. I think my father still has the pieces of his from when he ran a taxi company. No idea what sort of condition they're in, since the segments have been stacked up lengthwise on the ground for who knows how long, but y'know...potentially free.

--Patrick

#56

PatrThom

--Patrick

PatrThom

I'm visiting tomorrow, I'll ask.I am interested. I'm going to need another one at the end of the potential internet link, so if you wouldn't mind asking him about the size or make/model there's a possibility I'd make the trek to get it and put it to use.

--Patrick

#57

strawman

strawman

The company I work for makes mouthguards for sports. They're having a sale for a little while, and IIRC some of you play sports (we've even had roller derby players here...) so if you need a mouthguard for yourself or your youth, it might be something worth looking at. 15% off automatically applied in the shopping cart.

http://sisuguard.com

http://sisuguard.com

#58

Dei

Dei

Every roller derby player I know uses those mouthguards. They are the only ones I don't gag on.

#60

strawman

http://www.sovanightguard.com/

strawman

There are, but it appears they aren't on sale:Are there any models for bruxists? Or are they all athletic?

--Patrick

http://www.sovanightguard.com/

#61

PatrThom

products projects. And their prices don't look half bad, either.

https://www.ubnt.com/products/

--Patrick

PatrThom

Today I discovered this company. I think you might find some of their stuff interesting, especially with some of yourI'm going to need another one at the end of the potential internet link

https://www.ubnt.com/products/

--Patrick

#62

strawman

strawman

Yes, they are the first choice should anything come to fruition regarding my internet link. Their prices are very good for what they do.Today I discovered this company. I think you might find some of their stuff interesting, especially with some of your products. And their prices don't look half bad, either.

https://www.ubnt.com/products/

--Patrick

#64

PatrThom

PatrThom

So tell me...how excited should I be?

They're actually up to 5.1, btw, which includes some pretty hefty improvements for "just" a point release.

--Patrick

They're actually up to 5.1, btw, which includes some pretty hefty improvements for "just" a point release.

--Patrick

#65

strawman

strawman

Nice! I'm wishing I had time to set one up. When I do have time I won't have money though...